Search

Search

Search

Search

Successful run through 17,15 deg/30m dogleg in slim ID open hole

Download PDFMature Fields

Overcome the wellbore challenge of an unexpected extreme dog leg severity

North Sea, Norway

The major North Sea operator, Aker BP, was preparing for the last section of well construction. The 6 ½-in. openhole well was to be drilled into one of the flanks of the mature field as a water alternating gas (WAG) injector well. Because of high vibrations and occasional soft intervals in a relatively hard formation, an extremely high dogleg at 17,15 deg/30m was created, over a short distance from 5189m to 5225m of the ~1867m lateral.

Before the lower completion could be deployed, an alliance between Halliburton and Aker BP to analyze the challenging wellbore conditions was formed. Once all variables had been properly evaluated, a collective agreement was met to move forward in running the lower completion.

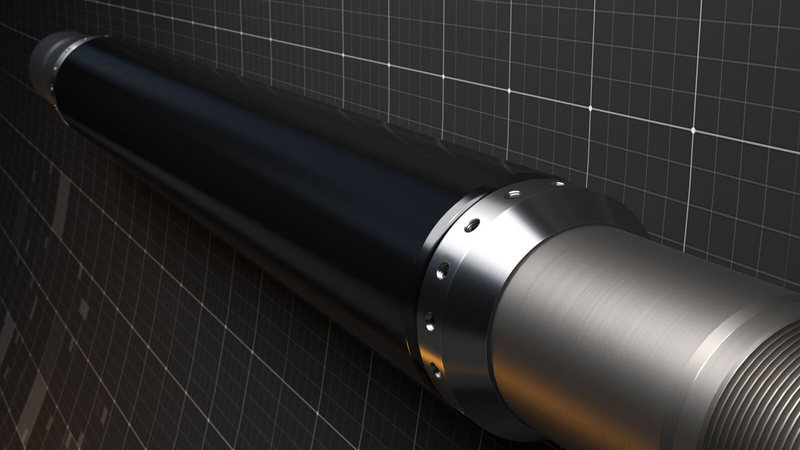

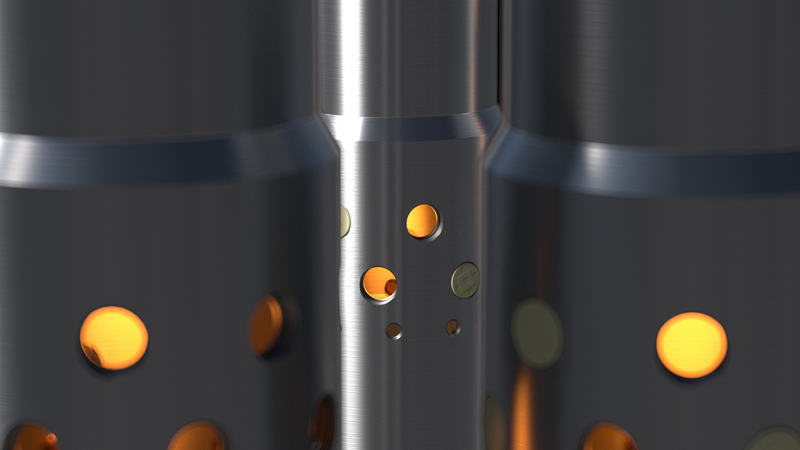

Through careful execution of the agreed procedure for the wellbore preparation and deployment, the lower completion, consisting of six Swellpacker® systems and 18 RapidShift sleeves on a VersaFlex® liner hanger system, was successfully deployed to the planned setting depth. Later in the completion operations during the coiled tubing campaign, each RapidShift sleeve was shifted open successfully.

Aker BP required specialized equipment at specific pre-planned depths within the offshore wellbore to achieve their objectives. In order to reach the planned setting depth, the lower completion must pass through a challenging wellpath trajectory, and any variation in placement from the planned depth could negatively impact the well objectives.

Working in alliance, Aker BP and Halliburton gained perspective and insight from local and global experts of both parties to analyze the wellbore challenges and come to a cohesive solution. The analysis included extensive WellPlan® software simulations to determine the torque and drag implications for deploying the specialized lower completion equipment through this challenging wellpath trajectory. Several iterations concluded that with the use of Halliburton’s VersaFlex liner hanger system in conjunction with centralizers below each Swellpacker system and RapidShift sleeve, the results would fall within the acceptance criteria. Furthermore, it was agreed that prior to deployment a second bit drift cleanup run would be performed for final pass-through verification through the challenging section of the wellpath trajectory.

Swellpacker systems

RapidShift sleeves

VersaFlex liner hanger system

successful lower completion

Collaborative efforts to fully understand and address the challenges, ensured the best customized solution to mitigate the risks effectively, and provide the highest chance of success to achieve Aker BP’s well objectives.

The combined efforts resulted in the successful deployment of the specialized lower completion to the planned setting depth. During the deployment, no additional weight was observed as the Swellpacker systems and RapidShift sleeves each passed through the challenging wellpath section, and the actual weight values were aligned with those expected from the WellPlan software simulations. Lastly, in order to meet the Aker BP’s objectives, during the coiled tubing campaign, all RapidShift frac sleeves opened as expected.

The Halliburton RapidShift stimulation and production sleeve system allows selective multi-zone stimulation treatment through the production string – cemented or open hole.

Download Data SheetSwell Technology

The Swellpacker system is based on the swelling properties of rubber in hydrocarbons, water, or both.

Download Data SheetLiner Hangers

The VersaFlex ELH system as a single unit contains an integral upper tieback receptacle, an ELH and a setting/running sleeve.

Download Data Sheet

With no moving parts and no inflation required to seal, swellable annular barrier packers remove the inherent risks of mechanical and inflatable tools.

Halliburton liner hanger portfolio includes expandable and conventional options for mature, unconventional, deepwater, and geothermal applications.

Maximize production with multistage fracturing completion systems that help reduce stimulation time and offer selective zonal treatment.