Search

Search

Search

Search

Operator doubles percentage of one-run curve/lateral section with less vibration compared to competitor bits.

Download PDFUnconventionals

Drill curve/lateral section with minimal drilling dysfunctions in a single run

Midland Basin / Texas

Customize the BHA design by:

An operator in the Midland Basin sought to optimize drilling performance and improve efficiency. Their goal was to design a bottomhole assembly (BHA) that would reduce drilling dysfunctions and complete the curve and lateral sections in a single run. To address these challenges, the operator engaged Halliburton. The objective was to achieve as many single-run curve/lateral sections as possible. This required a customized BHA design that incorporated a motorized rotary steerable system (RSS) with an iCruise® X intelligent RSS, along with a standard makeup length bit.

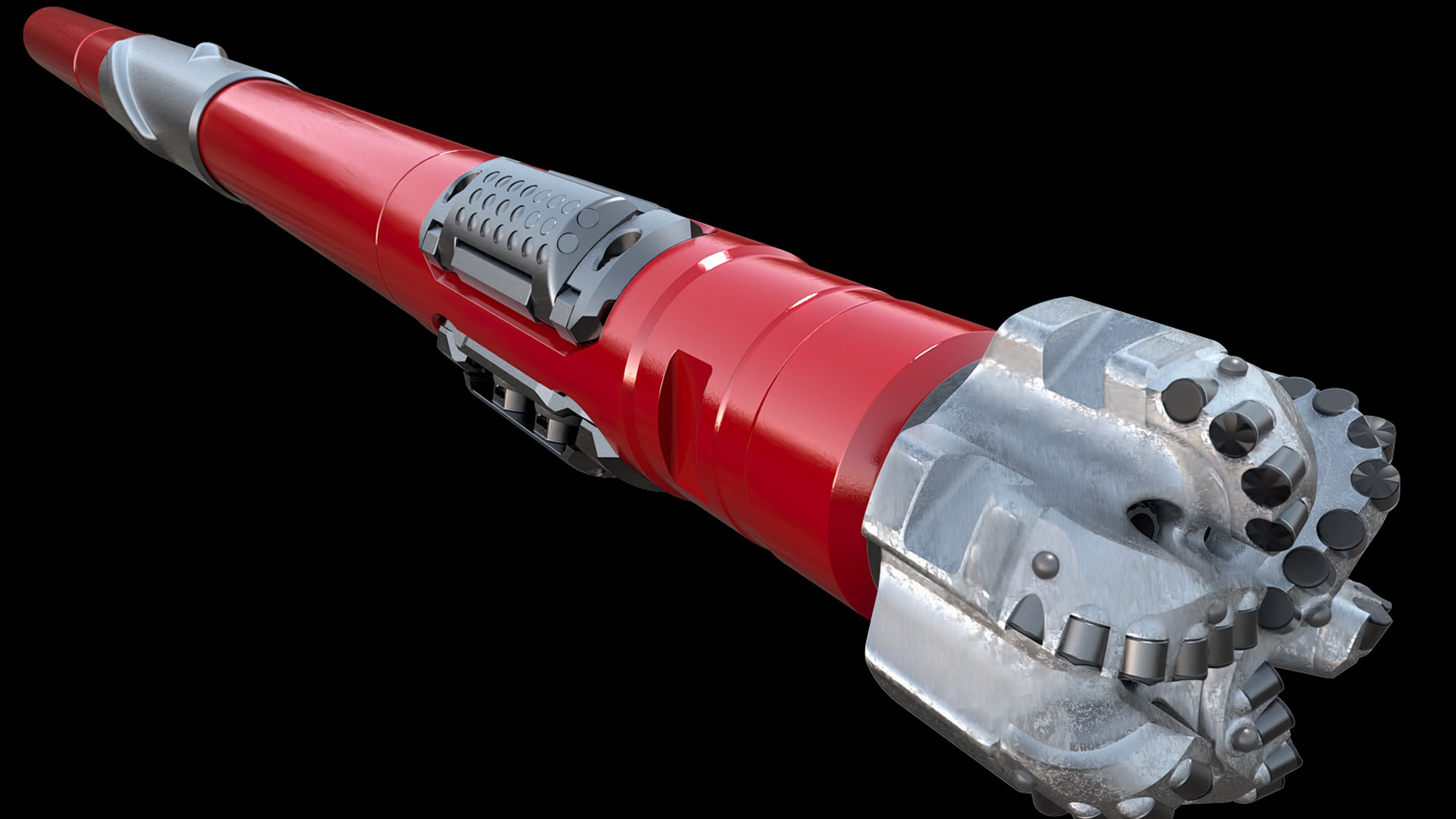

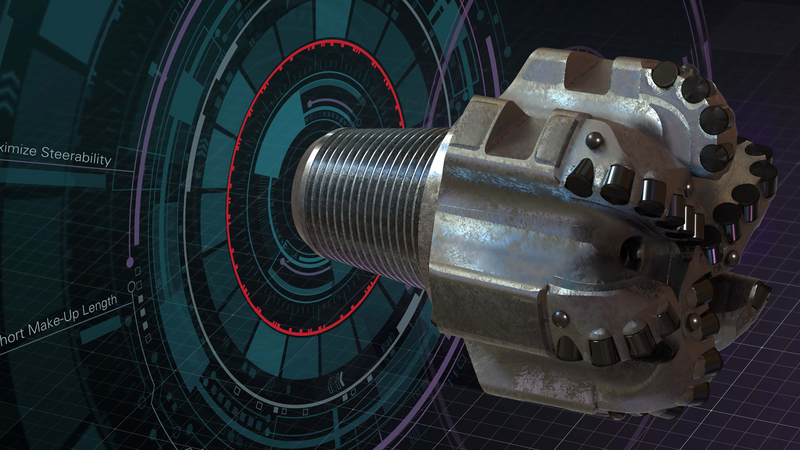

During the Design at the Customer Interface (DatCI™) design process, Halliburton identified a key improvement: remove the flex assembly from the motorized RSS BHA. By doing so, the operator could reduce shock and vibration when drilling into the lateral after completing the curve. This change would significantly increase the success rates for one-run curve/lateral sections and minimize the need for additional trips and BHAs. Halliburton chose the HyperSteer™ directional drill bit for this purpose. The HyperSteer bit’s shorter makeup length allowed removal of the flex assembly while still achieving the desired build rates necessary to land the curve within a specified window.

The HyperSteer directional drill bit outperformed competitor bits in terms of shock and vibrations in the lateral. As a result, the operator successfully completed curves without a flex assembly, achieving several one-run curve/lateral sections. This solution doubled the operator’s percentage of one-run curve/laterals. Furthermore, the initial BHA covered more footage, and less time was spent to change out the BHA in the lateral to remove the flex assembly.

Directional drill bits designed for high build rates in curve and lateral applications.

DatCI is a powerful service platform used to optimize bit and drilling performance through in-depth planning, bit design, and post-well evaluation.