Search

Search

Search

Search

Injector and producer lateral successfully completed to harness the earth’s energy for a consistent heat source

Download PDFLow carbon solutions

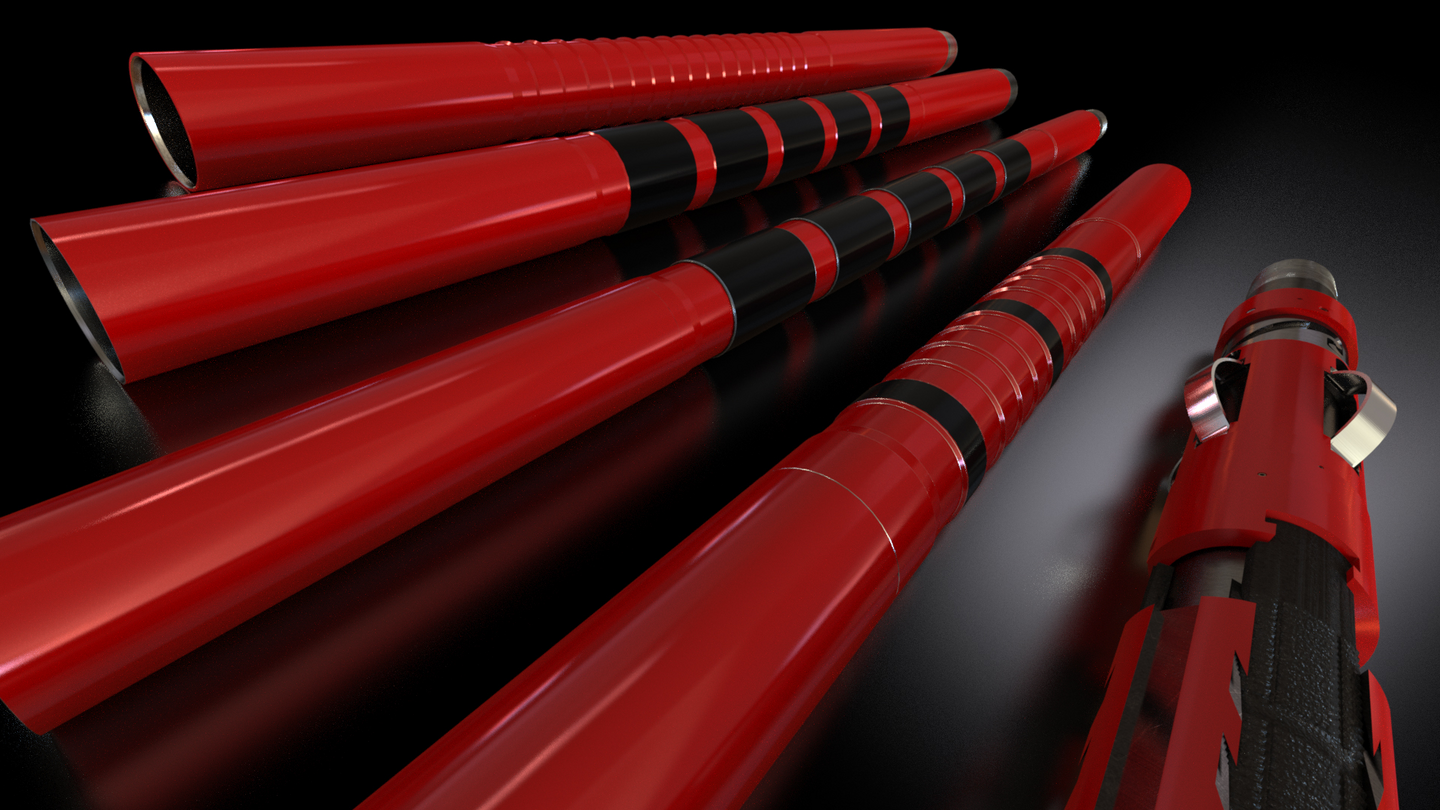

Provide equipment to withstand high temperatures and pressure post-fracture

United States

Halliburton worked closely with an operator to understand the challenges associated with enhanced geothermal wellbore conditions. Through iterative design and evaluation, Halliburton delivered a completion solution for the first greenfield development in the US. The completed wellbores enabled the operator to harness geothermal energy from a consistent heat source.

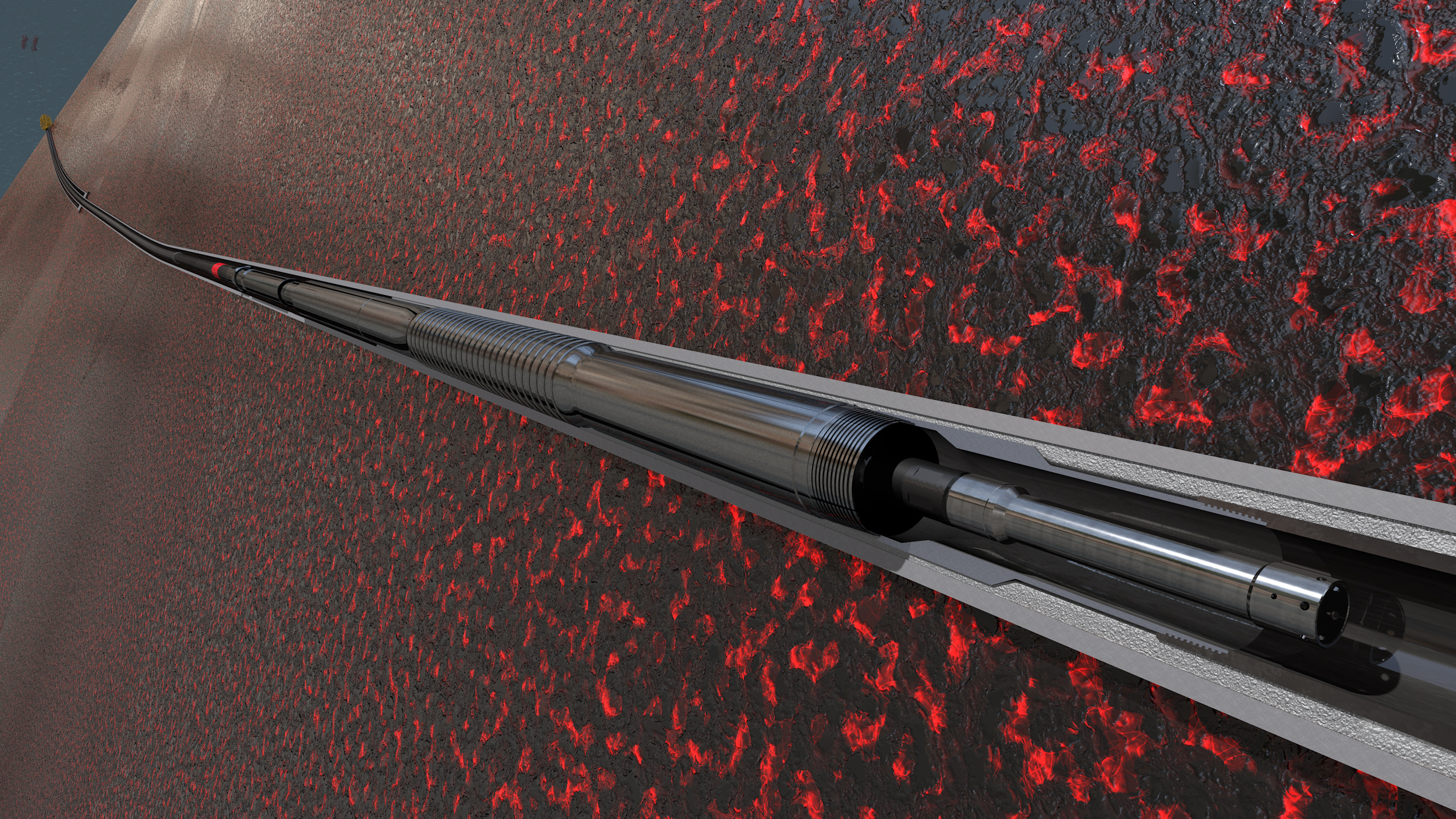

The successful completion of the wellbore construction phase post-drilling involved several key steps:

These steps were executed in both the injector and producer wellbores. The series of horizontal wells are installed alternating between injectors and producers.

After the wellbore construction phase, perforating and stimulation were performed at treatment pressures of more than 10,000 psi, which allowed the enhanced geothermal application to provide sustainable energy to a power plant. Additional wellbores are now planned to fully harness the formation’s potential and keep the power plant running using geothermal energy.

A VersaFlex® XSL-ZE expandable liner hanger (ELH) with a lower polished bore receptacle (PBR) was selected for the wellbore configuration. Equipment was set to run with a VersaFlex HWE ELH casing wiper plug, VersaFlex ELH landing collar, and Halliburton float collar and shoe with a tapered offset down jet. This equipment was deployed on a VersaFlex ELH running tool capable of withstanding washing and reaming operations. Halliburton provided a redesigned lead slurry with Thermavis additive to provide viscosity and create a stable slurry that did not set up while pumping, but rather developed strength under static conditions.

Rating for VersaFlex XSL-ZE ELH

Completed wellbores

Enhanced geothermal development in US

Halliburton delivered a completion solution for the first enhanced geothermal commercial project to deliver 24/7 non-intermittent geothermal energy from a consistent heat source. Pre-job engineering and collaboration allowed the successful execution of a well design that enables a plug-and-perf stimulation strategy to create the engineered reservoir between the injector and producer wellbores.

Building on the success of the initial wells, additional wells have been drilled and completed by Halliburton to support the operator’s goal of delivering sustainable power for the future.