Search

Search

Search

Search

Drilled interval 45% longer than the previous longest offset and improved ROP by 68%.

Download PDFDeep Water

Improve drilling operations for a deepwater exploration well

Guyana

With a focus on continuous improvement, an operator in the Caribbean regularly evaluates its technology needs. Their goal is to reliably drill each new well farther and faster, so they recruited Halliburton to improve drilling operations for a deepwater exploration well. The team determined they required a new bit design to enhance durability and performance compared to previous offset wells.

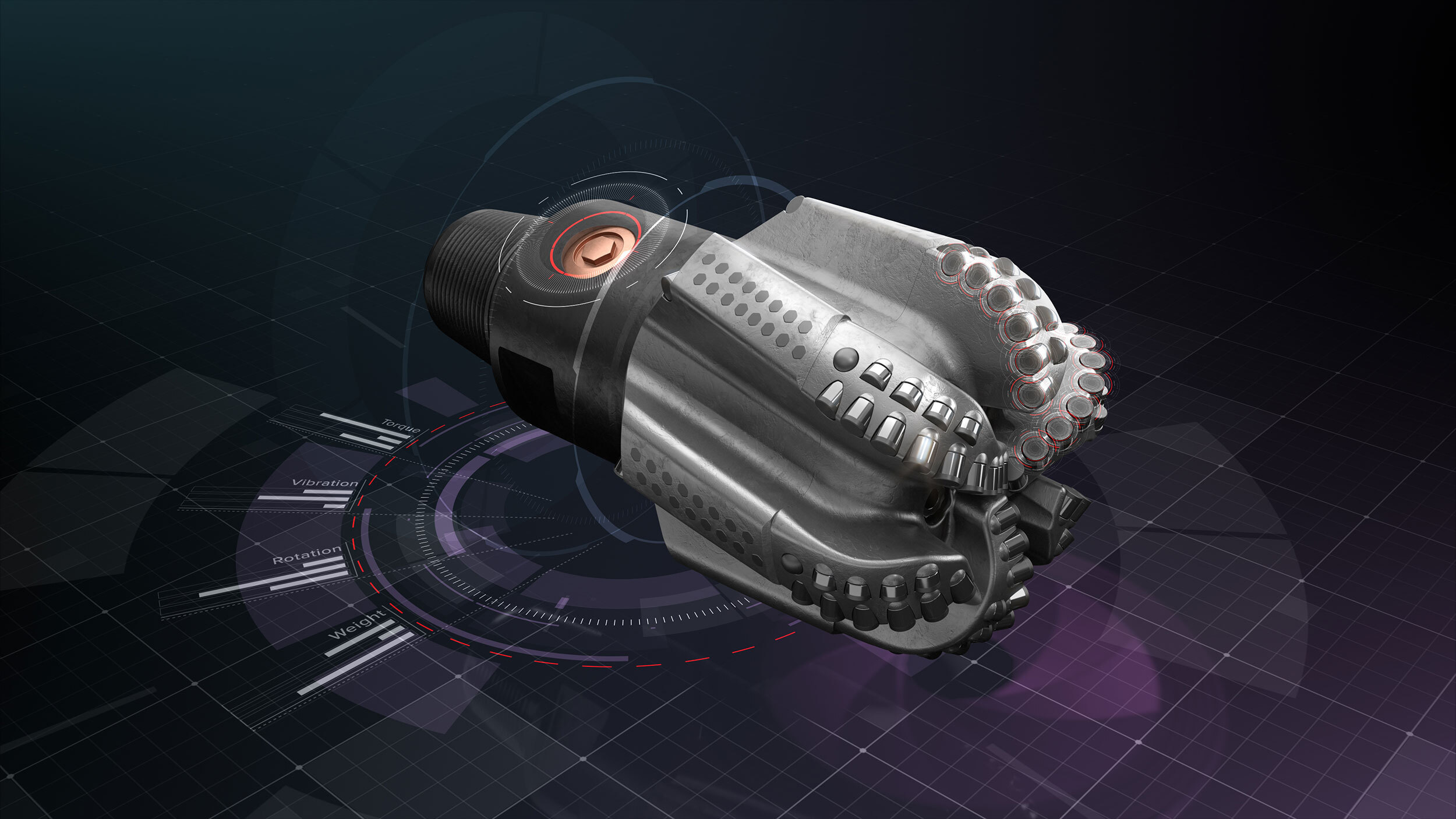

The team selected an 8-1/2-in. Hedron™ HDi75DMKF drill bit, which combines state-of-the-art technology with an industry-leading customization process to deliver the highest-performing, application-specific design on the market. The bit was designed using the design at the customer interface (DatCI™) process along with proprietary IBitS™ drilling software.

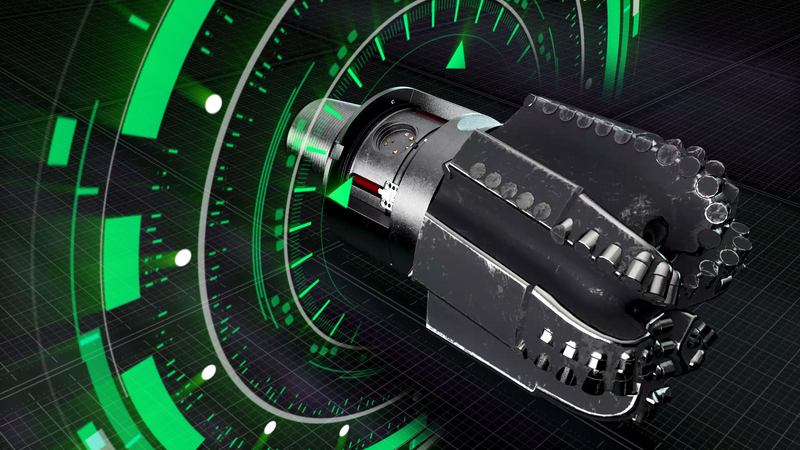

The bit was equipped with Razor™ 4D-shaped cutters specifically designed for the toughest and most abrasive applications. The bit was also outfitted with Cerebro Force™ in-bit sensing technology, which records weight, torque, bending, vibration, and rotational speed at the bit. Oculus™ automated dull grading technology was used to capture and precisely dull grade every cutter on the drill bit, allowing the design engineers to quickly identify trouble zones and optimize the bit design.

Longer interval than offset well

Faster ROP than previous record

The team drilled a 1,034 m section at an outstanding ROP of 27 m/hr. using the optimized bit configuration, reaching the planned measured depth (MD) to run wireline logs. This interval was 45% longer than the previous longest offset well drilled and ROP improved by 68% compared to the previous record. This resulted in operational time savings for the operator, and a report generated using the Cerebro Force in-bit sensing technology provided valuable field insight.

The Hedron® platform of fixed cutter drill bits combines state-of-the-art technology with an industry-leading customization process.

Geometrix™ 4D-shaped cutters use different geometries to optimize drilling efficiency and durability.

The Halliburton Cerebro Force™ in-bit sensor improves drill bit performance, giving operators data needed to optimize use for the length of a run.

Oculus™ is the first of its kind automated dull grading system that is fully integrated into the solution creation process.