Search

Search

Search

Search

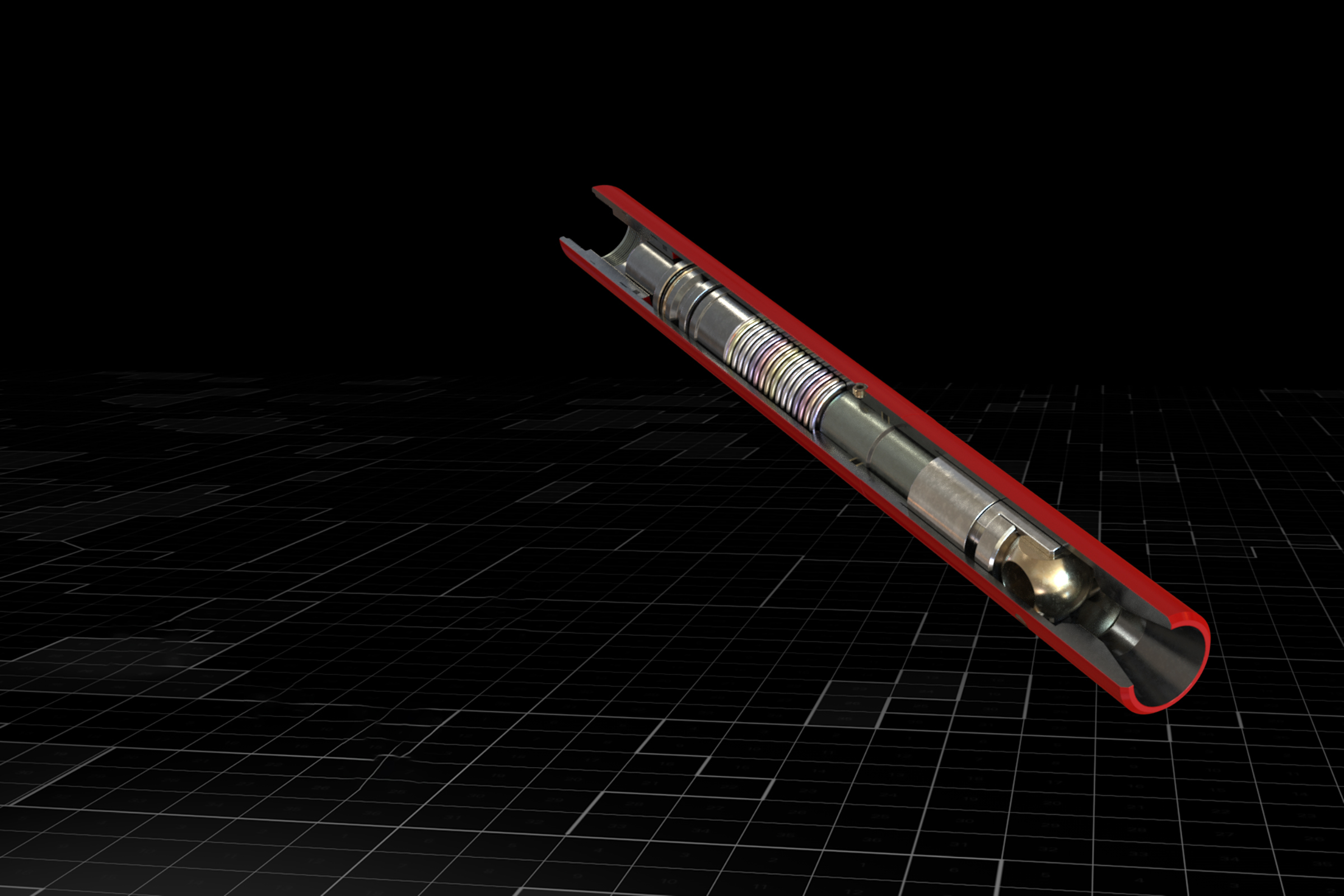

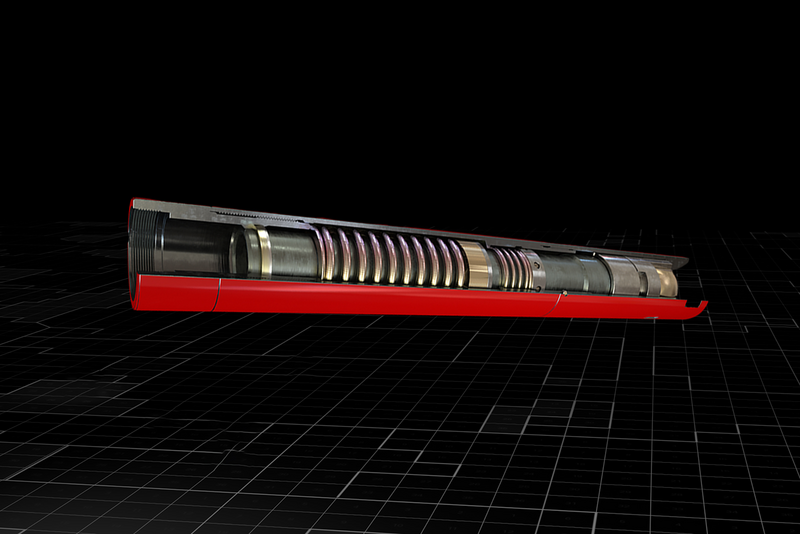

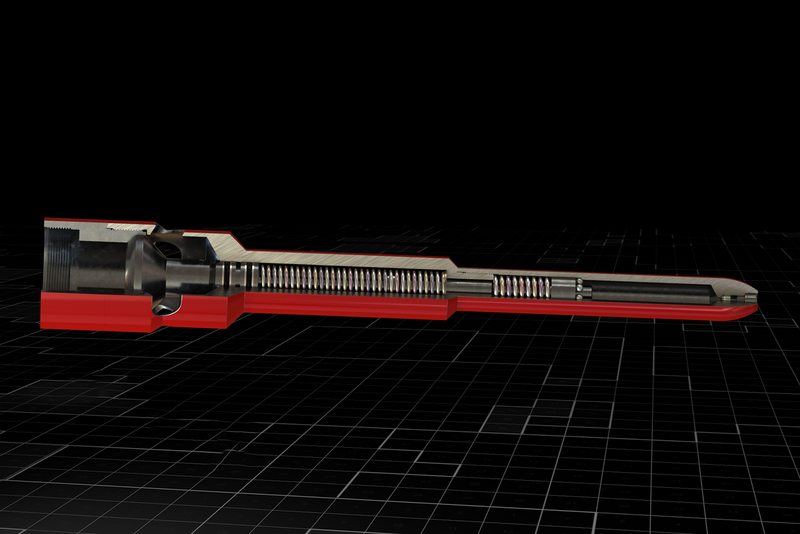

Storm Choke™ H safety valves are ambient-type, wireline-retrievable valves that are normally closed and pre-charged with a set dome pressure. When the well flowing pressure drops below the predetermined dome-pressure charge, as a result of a rupture in the flowline or surface equipment, the dome pressure and valve spring are designed to close the valve, shutting in the well.

The H valve is used in wells producing large volumes of abrasive fluids. Its large bore is not restricted by a flow bean. The valve is designed to resist pressure surges. A metal-to-metal ball and seat is used as the primary closure mechanism.

The H valve is ideal for protecting wells with declining bottomhole pressure because this valve is tubing-pressure sensitive instead of velocity sensitive. To reopen, the valve pressure must be fully equalized either by applying pressure in the tubing from the surface or by running a prong to allow equalization from below. The valve will reopen when the tubing pressure acting on the internal piston area overcomes the dome charge.

Storm Choke J safety valves are velocity-type, wireline- retrievable valves that are normally opened, direct-controlled valves.

Storm Choke K safety valves are ambient-type, wireline-retrievable valves with the largest flow area of all direct-controlled safety valves on the market. They are ideally suited for high-volume, low-pressure wells..

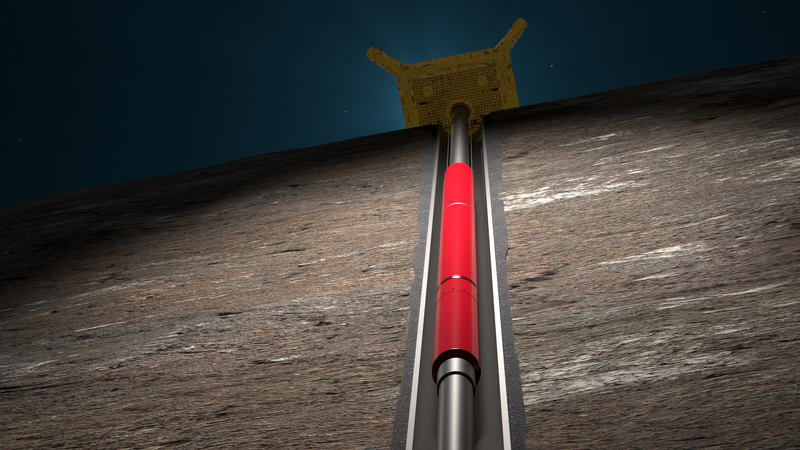

Halliburton tubing-retrievable and wireline-retrievable subsurface safety valves are a field-proven solution for operators.