Search

Search

Search

Search

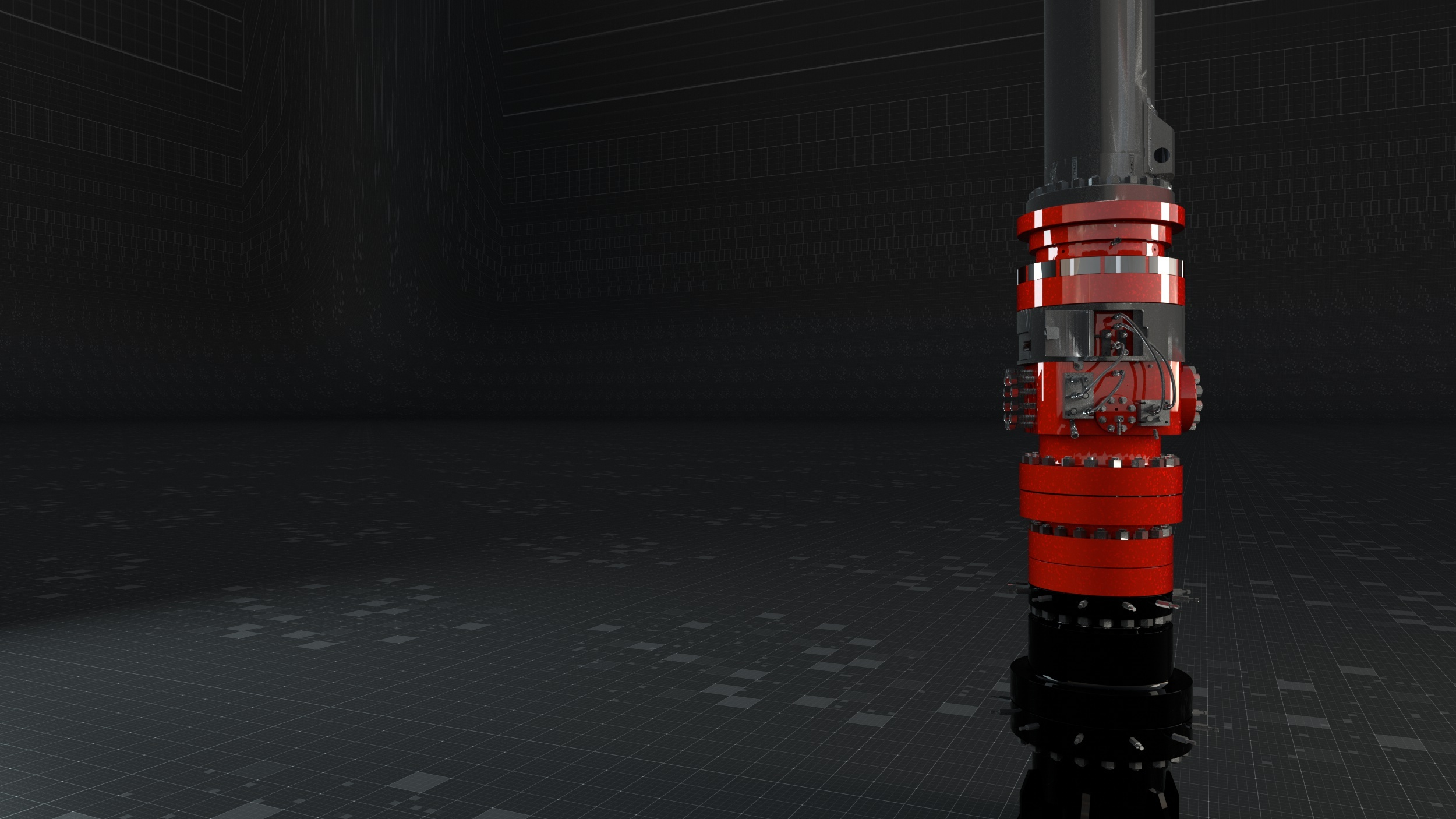

A key part of pressure control, Halliburton's rotating control devices are the first line of defense against fluid loss during critical operations.

talk to an expertWhen drilling scenarios demand precise flow control, Halliburton Rotating Control Devices (RCD) are essential. Halliburton RCD tools fit easily under most drilling rigs without modifications for better maneuverability. Operators save rig-up time and reduce the need for onsite inventory by changing stripper elements independent of the bearing assembly.

With a full suite of RCD tools for low, intermediate, and high-pressure applications, Halliburton provides safe and efficient containment throughout the process.

In addition, their compact design ensures an easy fit under most drilling rigs without modifications, providing better maneuverability and faster rig-up times.

An offshore rotating control device provides safe and efficient containment and diversion of fluids throughout the well construction process.

01:32

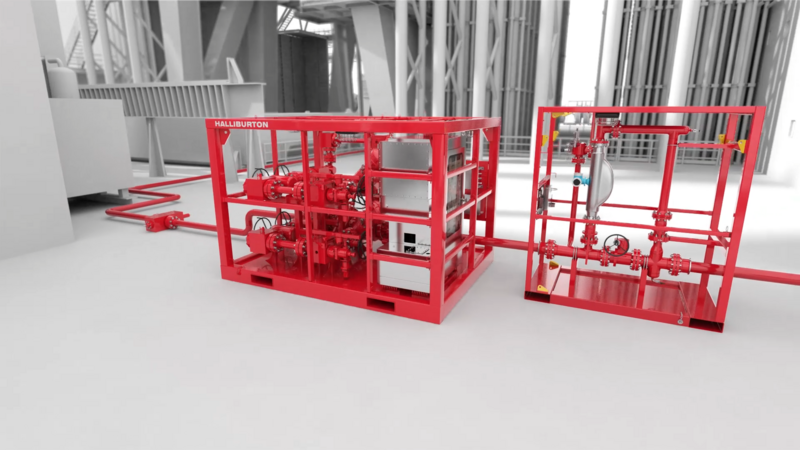

MANAGED PRESSURE DRILLING SERVICES

Innovative design makes element changes easy and predictive. The unique remote bearing latch system improves element and bearing changes.

Read data sheetHalliburton offers a series of rotating control devices suitable for a range of applications including managed pressure drilling and underbalanced drilling, where flow control is critical to success.

In addition to the proven RCD 5000™ device for high pressure applications, Halliburton's proven Diamond Rotating Head technology adds low and intermediate operating pressure capabilities with RCD 1000™ and RCD 2000™ tools.

The Halliburton suite of RCD tools features stripper elements that can be changed independent of the bearing assembly, saving rig time and reducing onsite inventory at the rig. They are available in rotating head sizes from 7-1/16-inch 3000 psi to 30-inch 2000 psi inlet flange; and weld-on connection sizes in 16, 20, 24, and 40 inches.

A compact design ensures an easy fit under most drilling rigs without modifications, providing better maneuverability and faster rig-up times.

Our latest offshore rotating control device provides safe and efficient containment and diversion of fluids throughout the well construction process.

The unique remote bearing latch system improves element and bearing changes. The entire bearing assembly can be released and hoisted to the rig floor using the drill pipe. At the rig floor the bearing can be serviced and the elements can be changed. Also available is a dual element configuration that can be deployed through the rotary table.

This reliable rotating control device provides a robust means of safely diverting flow from the annulus away from the rig floor. Complementing the traditional BOP stack, the RCD maintains a dynamic seal on the annulus, making it possible to control annular pressure at the surface using chokes to control the influx of formation fluids while drilling proceeds.

Enabling technology that can accomplish efficiency goals while mitigating drilling risks.

The Halliburton e-cd™ circulating device is an Eni-patented system used in managed pressure drilling operations

Halliburton's underbalanced drilling service delivers high-performance drilling solutions while focusing on improving reservoir recovery.