Search

Search

Search

Search

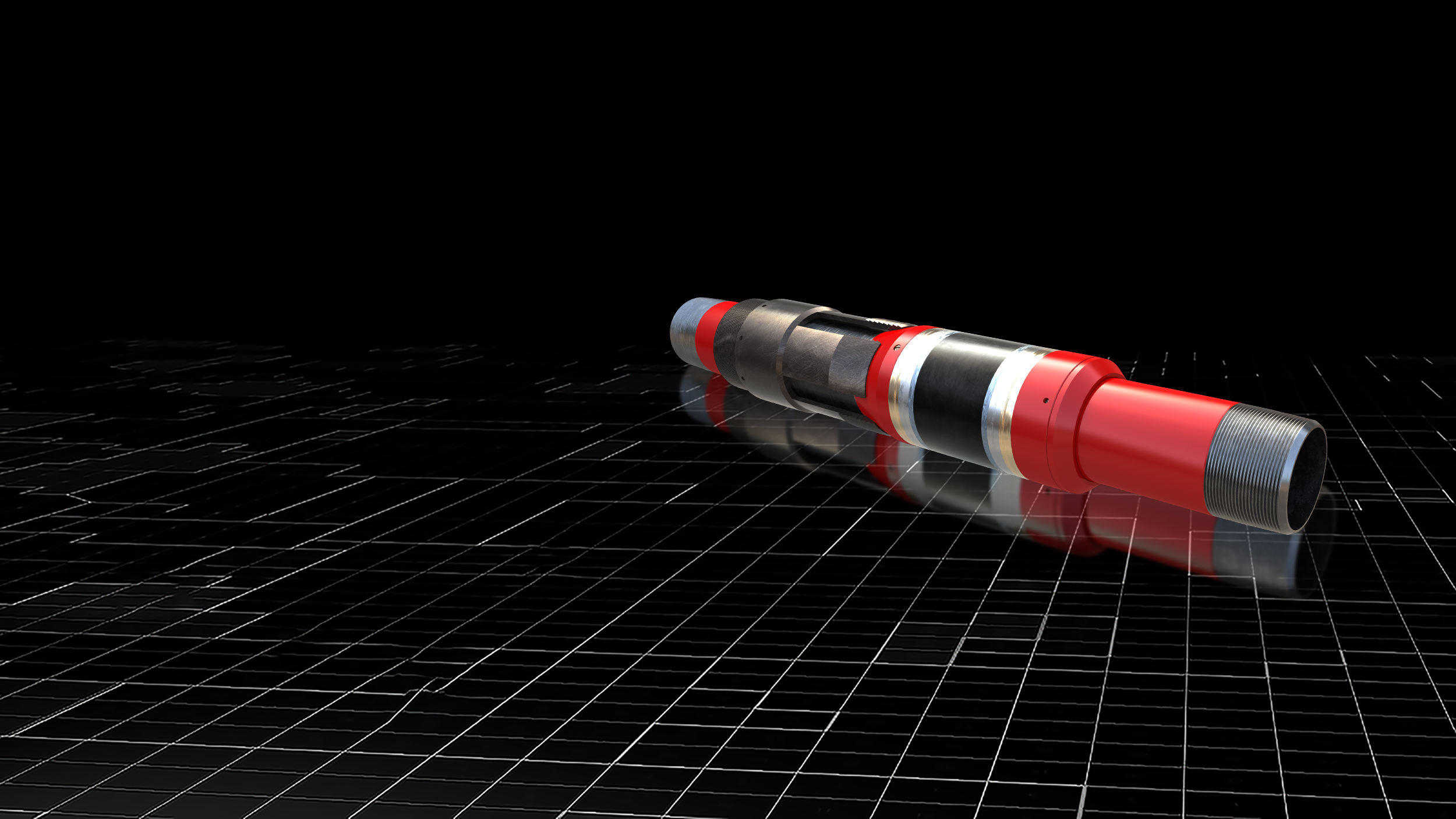

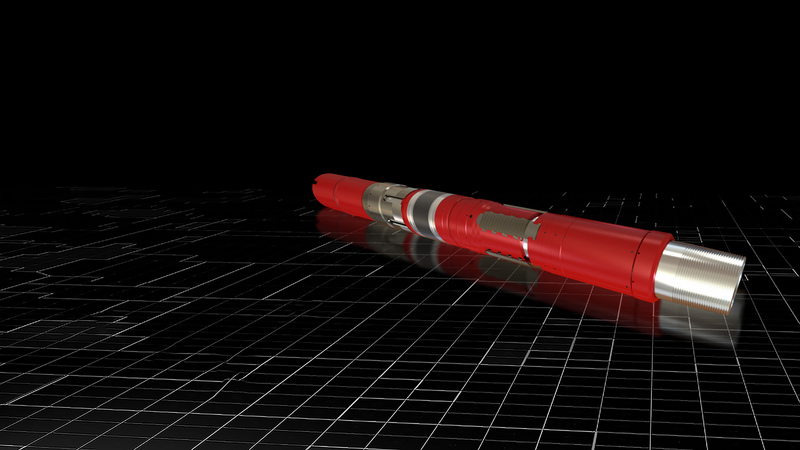

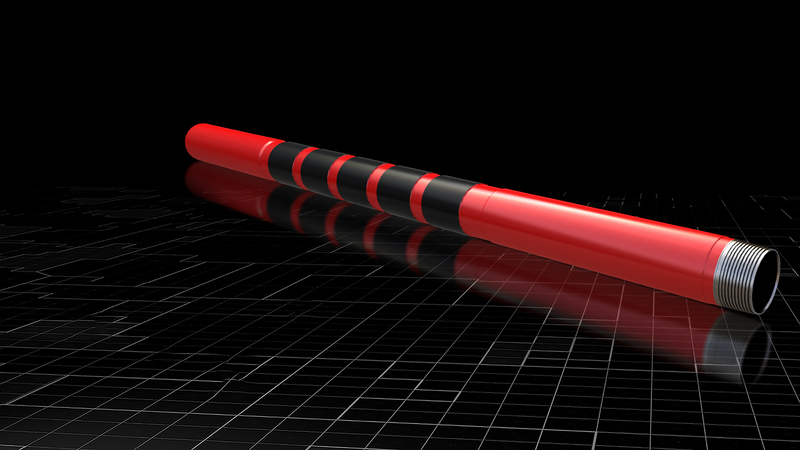

Integral liner hanger system for highly deviated or horizontal wells

Talk to an expertHalliburton MatchSet hydraulic-set conventional liner hanger with integral liner-top packer has a unique compact design for highly deviated or horizontal wells. The hanger is equipped with premium O-rings and glass-filled Teflon backup rings to seal in the hydraulic cylinder. A high-strength alloy cylinder provides maximum burst and collapse rating.

The hanger is set by applying pressure through the drillpipe. A setting ball is circulated or dropped to the ball seat in the landing collar or running tool. Applied pressure acts on an internal piston, moving the slips up the cones to the set position. The hydraulic-set liner hanger incorporates a tapered roller bearing assembly, if required, which allows the liner to be rotated in the set position while cementing the liner.

The liner-top packer is a high-performance packer that is suited for most applications and sets by applying set-down weight. The packer provides an effective annular seal between the top of the liner and the parent casing, preventing formation breakdown, loss of cement slurry, and gas migration above the liner top during the life of the well. The liner-top packer features hold-down slips, making it suitable for use in deviated or horizontal wells. Connection to accept an upper tieback receptacle is standard.

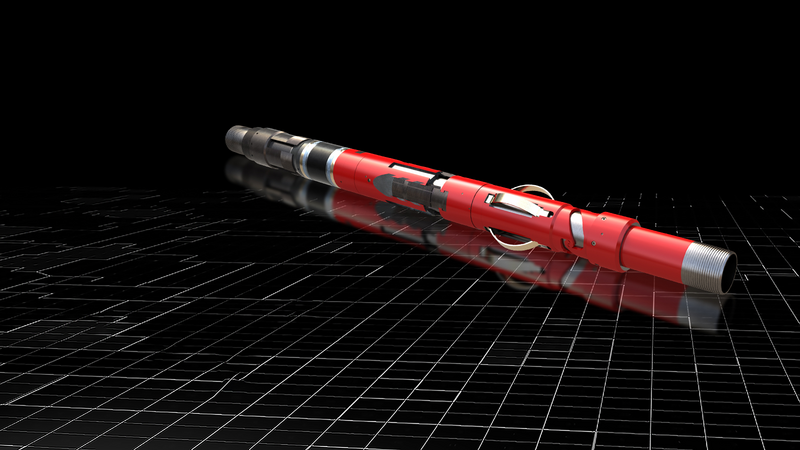

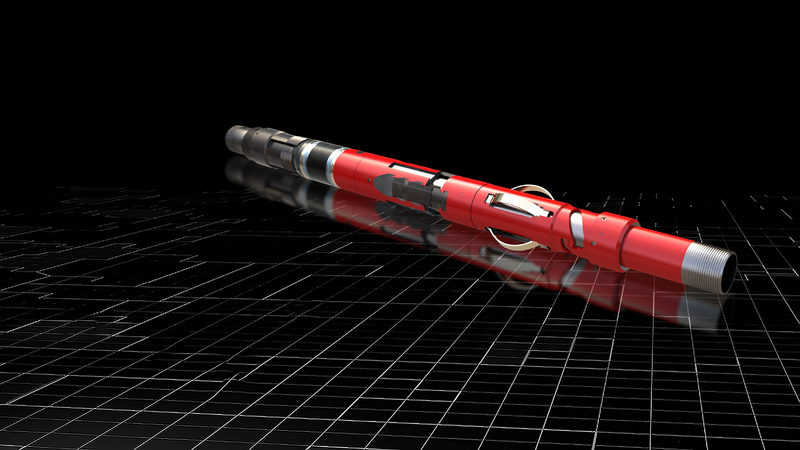

Protected slips designed for highly deviated or horizontal wells

Protected slips designed for pressure-sensitive formations

Integral liner hanger system for pressure-sensitive formations

Liner Hanger

Liner-top packer

Halliburton liner hanger portfolio includes expandable and conventional options for mature, unconventional, deepwater, and geothermal applications.

Field-proven, total system approach to liner installations

Offer system configurations for cemented and non-cemented land solution applications