Search

Search

Search

Search

Remotely actuate downhole flow control devices using direct hydraulic control lines from the surface

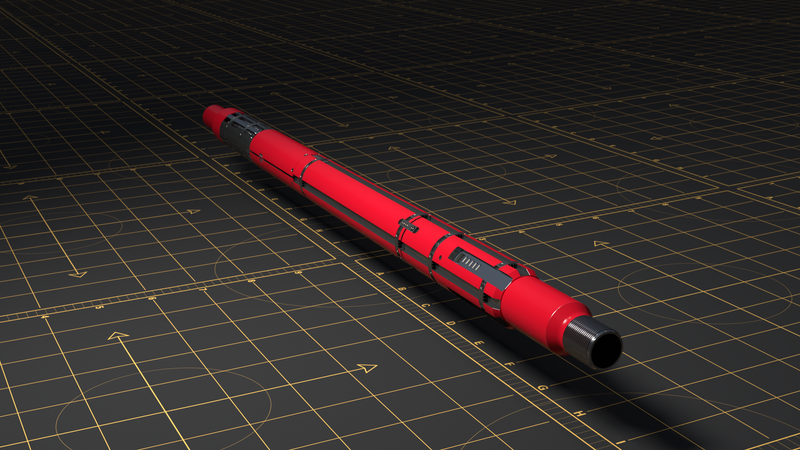

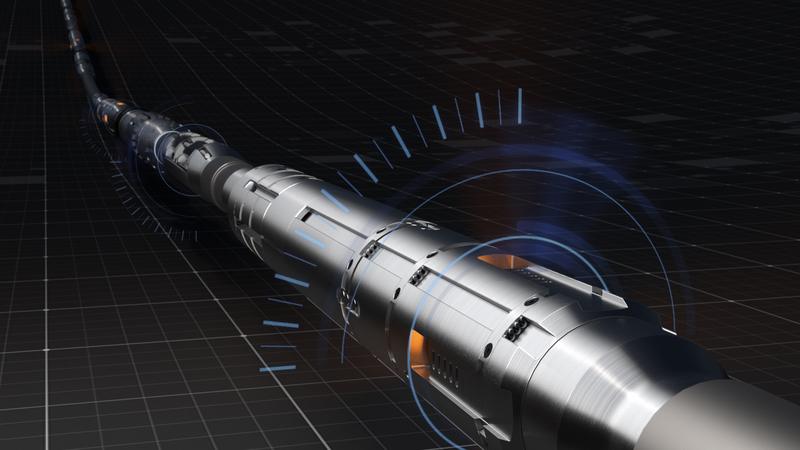

Talk to an expertThe direct hydraulics downhole control system uses direct hydraulic control lines from the surface to remotely actuate downhole flow control devices, such as interval control valves (ICVs). ROC™ permanent downhole gauges and Venturi flowmeters and densitometers can also be used in conjunction with the Direct Hydraulics system for measuring downhole pressure, temperature, and flow rate.

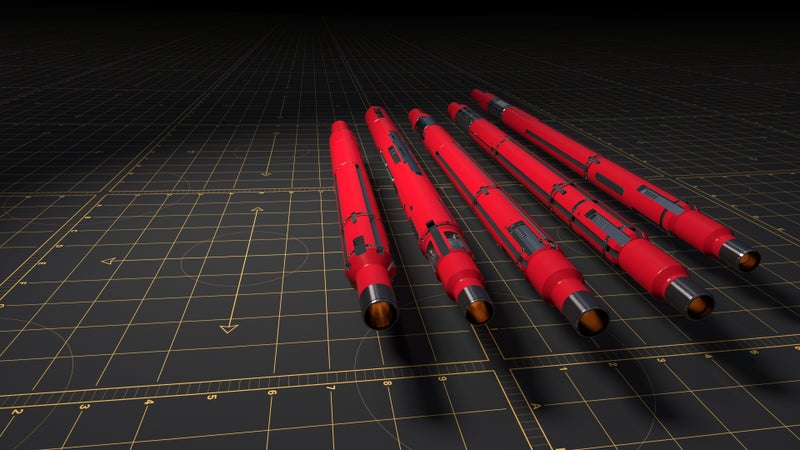

The direct hydraulics system provides on/off or variable control of flow into or out of reservoir intervals and can be used in onshore, platform, or subsea applications.

The direct hydraulics system controls all Halliburton intelligent hydraulic flow control equipment, providing simple and reliable zonal control for even the most complex intelligent wells.

A typical direct hydraulics system includes an ICV, an Accu-Pulse™ hydraulic positioning module, and a zonal isolation packer, such as the HF-1 packer. For control of a single ICV, two control lines are run from the surface, with one attached to the open side of the piston and the other attached to the close side. Pressure applied to one line, rather than the other, drives the piston to the corresponding position. Because the piston is rigidly attached to the ICV opening mechanism, piston movement operates the valve. This feature can dramatically improve the ability to shift a stuck sleeve due to scale buildup.

The Accu-Pulse™ module enables incremental opening of a multi-position ICV to control produced or injected fluid rates for enhanced reservoir management.

The SmartPlex® II downhole control system is an electro-hydraulic multi-drop system that provides reliable zonal control of multiple valves in a single wellbore.

The debris-tolerant HS interval control valve (HS-ICV) enables deployment of Halliburton SmartWell® systems in high-pressure, deepwater environments.

Next-generation electro-hydraulic control system delivers fast, precise, bidirectional choke control and manages up to 12 ICVs using only three control lines

Halliburton SmartWell® completion systems allow you to collect, transmit, and analyze completion, production, and reservoir data and control and monitor selected reservoir zones remotely and in real-time.

Halliburton intelligent flow control systems provide a method to integrate manual or automated surface control systems with downhole SmartWell® completion equipment.