Search

Search

Search

Search

Modern downhole pressure and temperature technology for low-carbon solutions

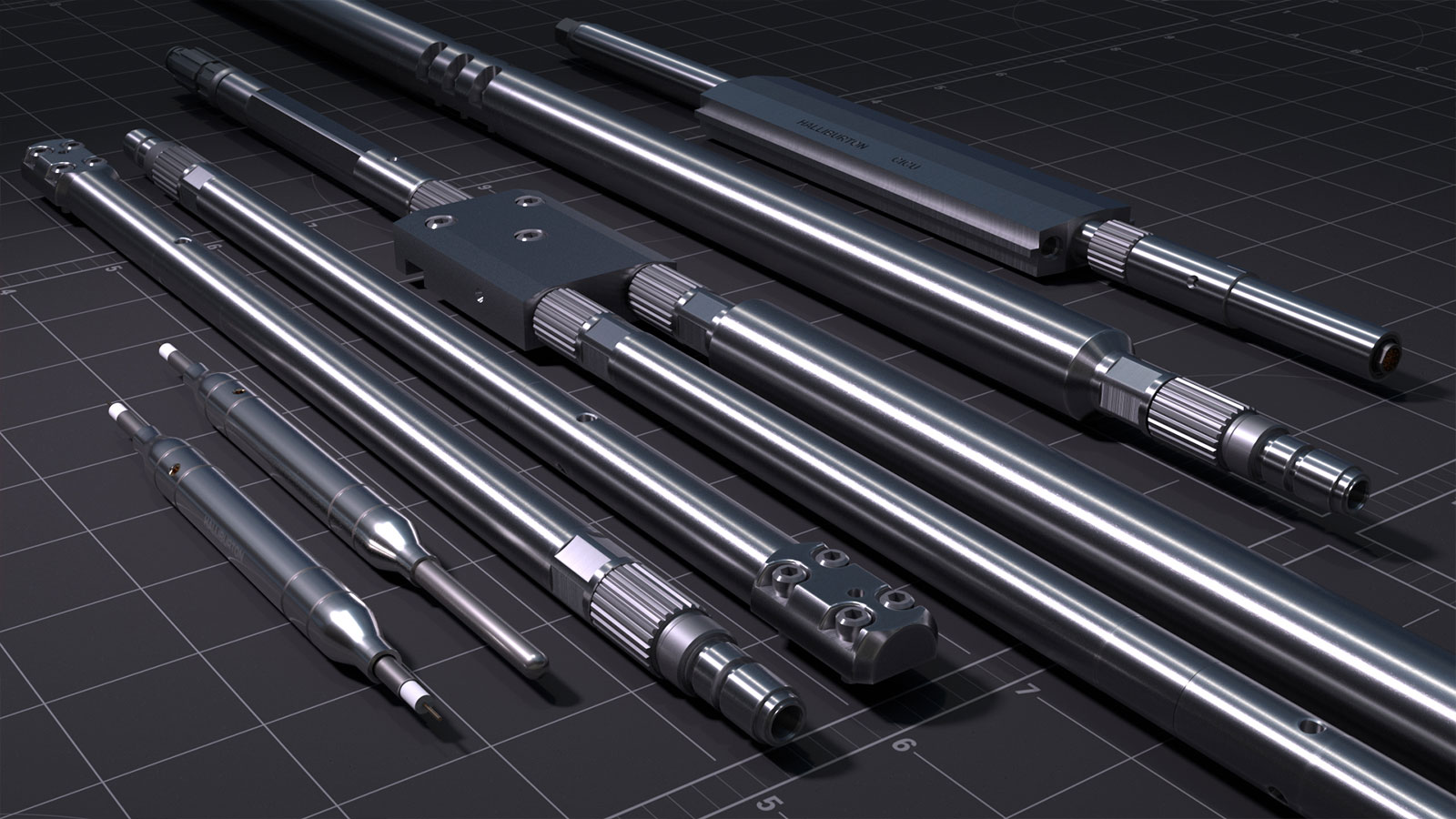

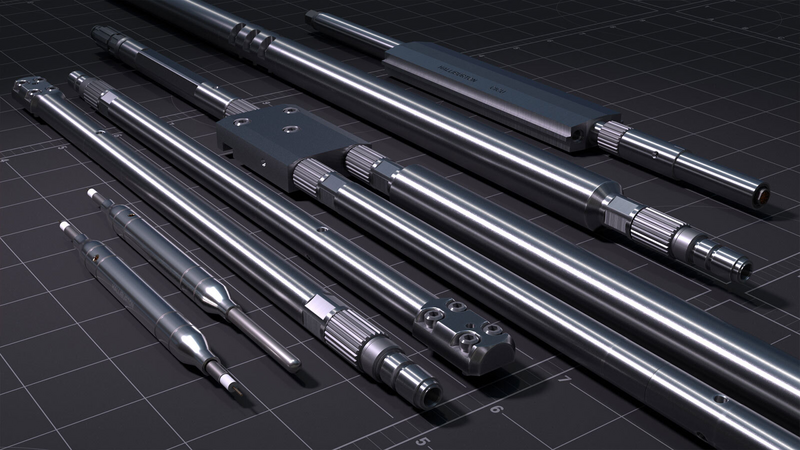

Talk to an expertOur robust CO2 well design includes in-well sensing technology and continuous parameter collection. Downhole sensors address conformance and containment risks using the Opsis® and LinX® electric and fiber-optic technology portfolios. The combination of fiber-optic technology and electronic gauges are commonly employed to mitigate CO2 injection uncertainties and ensure regulatory compliance. Opsis® CS and LinX® permanent downhole gauges provide reliable in-wellbore and behind casing, real-time, long-term data for reservoir characterization. Fully customizable, the gauges are essential to monitor injection and help verify CO2 containment.

The Array CS system provides a slimline electronic gauge design for distributed pressure and temperature sensing. Sensors are embedded into the TEC during manufacturing to provide the customer with a seamless and customizable solution. Using industry-proven resonating quartz crystal sensors, Opsis, Array, and LinX systems provide long-term monitoring for low-carbon solutions. These systems use the latest generation of ASIC electronics to provide highly accurate pressure and temperature data calibrated down to -35°C and proven survivability to -80°C.

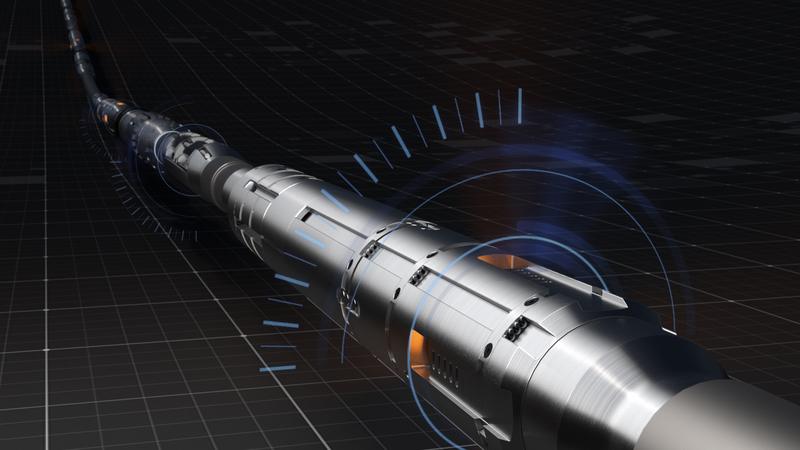

Fiber-optic monitoring allows vertical seismic profiling (VSP), micro-seismic monitoring (MSM), and the assessment of external and internal mechanical integrity testing (MIT) of wellbores. Trigger events that indicate containment risk are derived in real time from distributed acoustic sensing (DAS), distributed temperature sensing (DTS), and distributed strain sensing (DSS).

Halliburton SmartWell® completion systems allow you to collect, transmit, and analyze completion, production, and reservoir data and control and monitor selected reservoir zones remotely and in real-time.

The DataSphere permanent monitoring suite is a robust combination of the best in sand control, multilateral and intelligent completion technology.