Search

Search

Search

Search

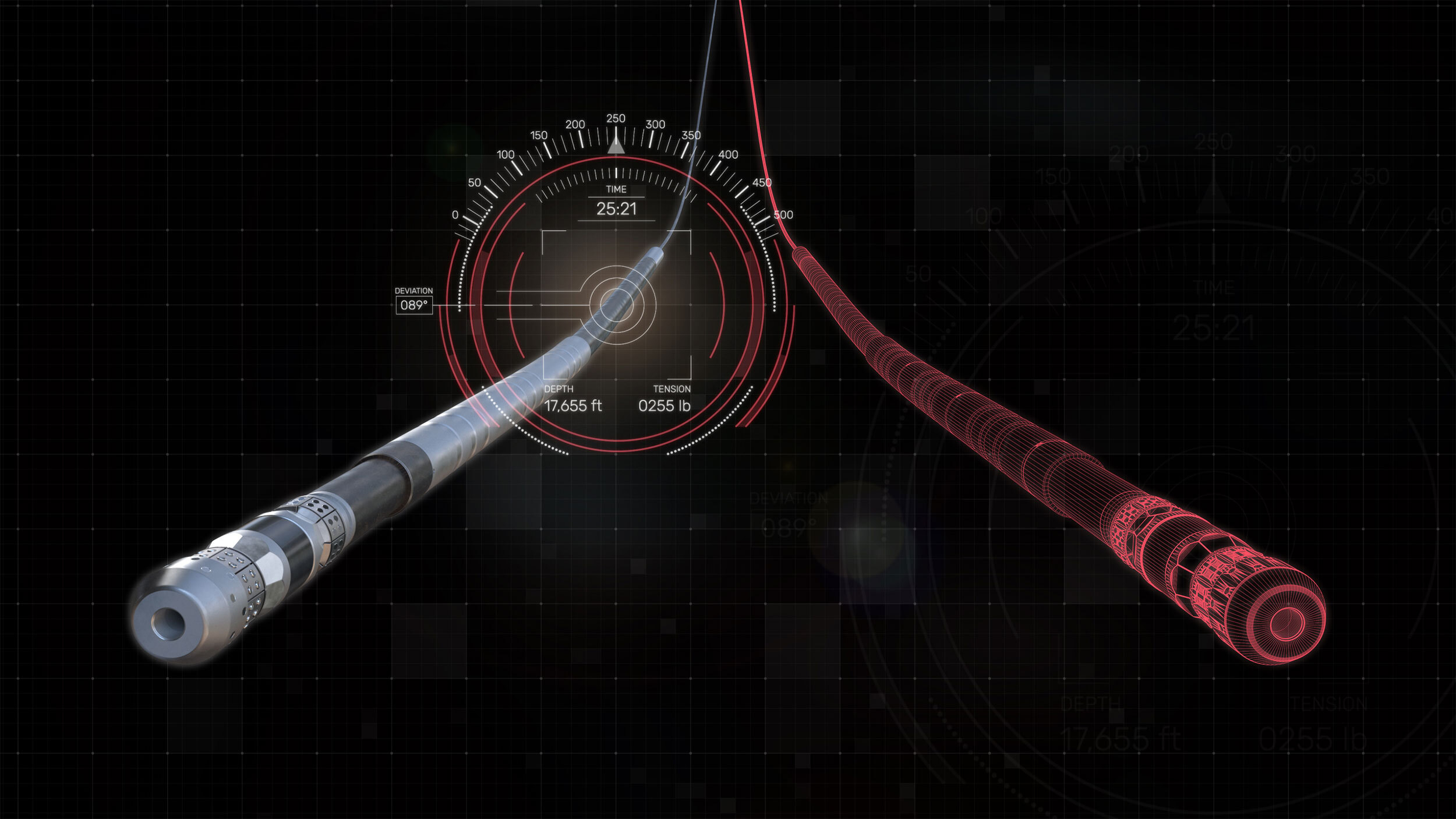

OCTIV Auto Pumpdown controls fluid pumps and a wireline unit as a single, fully automated, closed-loop system to maximize plug and perforating performance

Talk to an expertThe OCTIV Auto Pumpdown service controls fluid pumps and a wireline unit as a single, fully automated, closed-loop system to maximize Halliburton’s plug and perforating performance and efficiency. The system executes operations to plan and optimizes equipment operation for improved consistency.

OCTIV Auto Pumpdown enhances operations by automating tasks previously prone to human inconsistencies. The service reduces risk by providing prompt feedback to dynamic downhole conditions, which helps prevent unplanned and costly interventions. These improved consistencies create more efficient operations and reduce required fluids for tool conveyance.

OCTIV Auto Pumpdown responds to each wellbore trajectory and unique well characteristics to perform a more efficient operation with minimal fluid. Using the wellbore survey, tally, and a real-time digital twin, the service continuously calculates a forward-looking model of the wellbore to anticipate speed and rate changes as the tool string is conveyed.

Cost per year from wellbore-caused wireline NPT

Pumpdown water wasted per year from inefficiency

Coiled tubing jobs avoided by running Auto Pumpdown

During a typical completion, operational inconsistencies can arise from variable downhole conditions, surface equipment, and even personnel competency. By reducing the impact of human variance, automation enables higher job efficiency, reliability, and increased pumping hours. Combined with the eWinch perforating unit, OCTIV Auto Pumpdown sets the standard in fluid, emissions, and fuel reduction for plug and perf operations.