Search

Search

Search

Search

Manage wellbore debris and improve wellbore cleanup with downhole solutions designed for optimized well life

Talk to an expertOperators face a range of challenges that demand precision and efficiency in drilling, completions, production, and abandonment. To minimize downtime, ensure wellbore stability, and maximize production output, they require reliable wellbore service tools. These tools are crucial for zonal isolation, remedial repairs, and optimized well performance throughout the entire well lifecycle.

Halliburton delivers a comprehensive portfolio of wellbore service tools and technologies designed to tackle any operational challenge. We offer innovative solutions for every phase of well construction, intervention, and abandonment. Our portfolios include API 11D1-qualified service packers, well suspension tools, advanced wellbore cleanup, and displacement solutions. Halliburton provides operators with proven and reliable downhole solutions that reduce rig time, improve efficiency, and boost asset value.

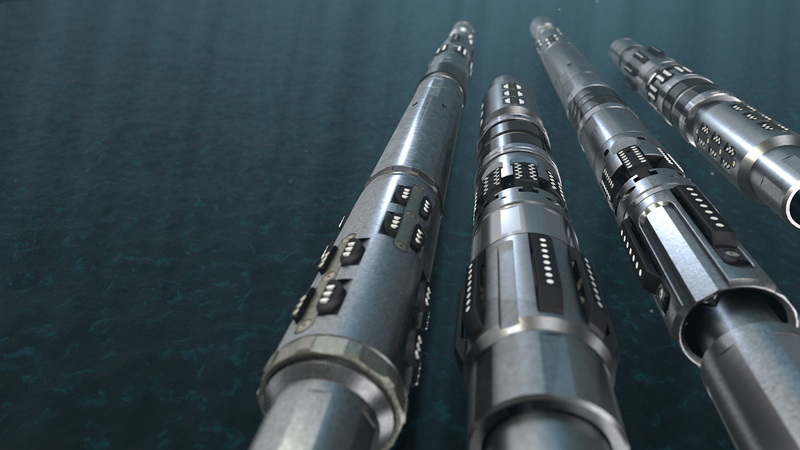

Debris left in the wellbore after drilling can obstruct operations, damage equipment, and increase non-productive time. Our CleanWell® solutions provide a range of specialized tools, including casing cleaning, debris extraction, jetting and bypass, riser cleaning, and specialty tools. These solutions effectively remove debris and scale, which minimizes equipment damage and non-productive time. This enables operators to maximize production and reduce costly remedial interventions throughout the well construction process.

Precision-engineered tools and advanced solutions improve well productivity. Our comprehensive perforating suite optimizes the connection between the wellbore and reservoir to ensure efficient and reliable perforating. Engineered for flexibility, safety, and high performance, our solutions help deliver reliable results even in the most challenging downhole environments and operational scenarios.

Well suspension tools act as reliable downhole barriers. They create gas-tight seals at predetermined depths within the wellbore tubing or casing. Operators rely on these tools to maintain wellbore stability and security amid temporary suspension activities like BOP (blowout preventor) testing, casing integrity checks, or emergency shut-ins caused by weather emergencies or adverse conditions. Retrievable bridge plugs and service packers help operators ensure operational continuity, maintain compliance, and protect personnel and the environment.

Sand production and scale buildup can damage downhole equipment, reduce flow efficiency, and complicate well interventions.

Advanced cleaning tools from Halliburton target organic and inorganic deposits. These specialized downhole solutions remove sand and particulate debris from the wellbore, which protects flowlines and production facilities. High-pressure jetting systems effectively clean scale buildup without damage to your equipment.

case study | middle east

Halliburton collaborated with a major Middle East operator to perform critical casing integrity pressure tests in high-profile wells by deploying RTTS® packers.

read case studycase study | gulf of america

PowerMag® casing magnets deliver unmatched debris recovery during deepwater window milling operations. More than 7,500 lb of metal removed.

read case studyOperators require effective wellbore isolation to perform testing, treatment, and cement squeeze activities. Halliburton offers a full-opening, retrievable packer designed to create a reliable seal in the wellbore. This allows operators to control fluid flow, perform pressure tests, sample fluids, treat specific zones, or perform multiple interventions in a single run. These tools help reduce rig time, lower costs, and maintain well integrity throughout the well’s lifecycle.

To minimize environmental impact from wellbore operations, operators need to reduce risks and deliver tangible results. Halliburton offers wellbore cleanup solutions designed to minimize waste fluids and improve the efficiency of filtration methods. These tools help operators meet regulatory requirements, reduce environmental risks associated with debris and fluid disposal, and maintain operational excellence.

Innovative technologies and optimized workflows address complex well conditions, regulatory requirements, and technical challenges. Our P&A tools use advanced systems such as digital slickline systems and pipe severing tools. This improves efficiency and saves rig time. We help you streamline operations with integrated services and proprietary workflows and optimize costs at each stage of the P&A process with a phased approach.

Reduce well construction costs with the latest-generation of filtration services, wellbore cleanup fluids, mechanical wellbore cleaning tools, and optimized software modeling.

Halliburton perforating solutions offer industry-leading technologies, tools, and techniques with an unequaled success and safety record.

Isolate portions of the well to perform remedial repairs in versatile and economical ways.

Enable a wide range of well support operations, save time, and reduce risk with Halliburton retrievable well suspension tools.

Halliburton provides the technology and expertise to facilitate safe and efficient operations worldwide for Plug & Abandonment solutions.